Production of our knives

All knives we sell are made entirely in my own workshop.

Here I link a video about the production of the model UK1

The blade grind

Grinding the blade is the step in knife making that requires the most precision, time and concentration.

I use a specially adapted surface grinding machine for this.

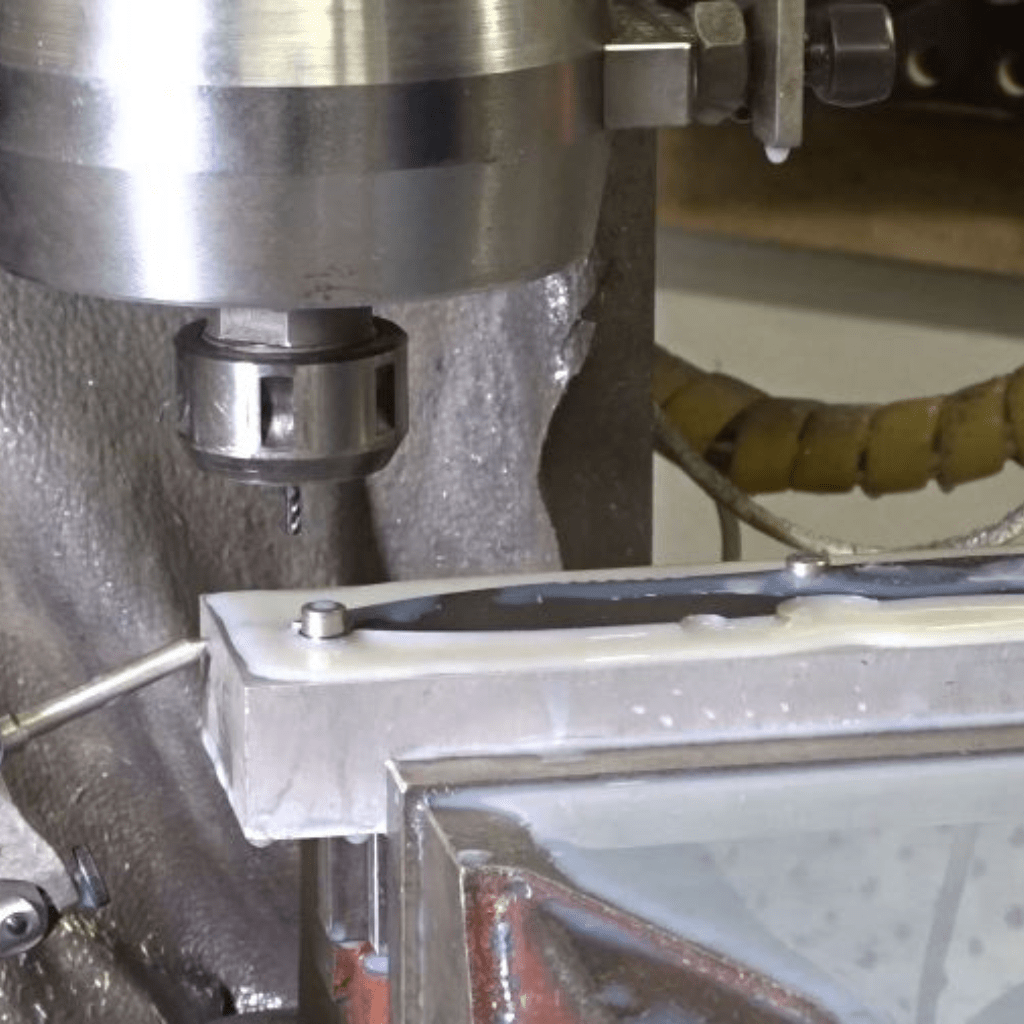

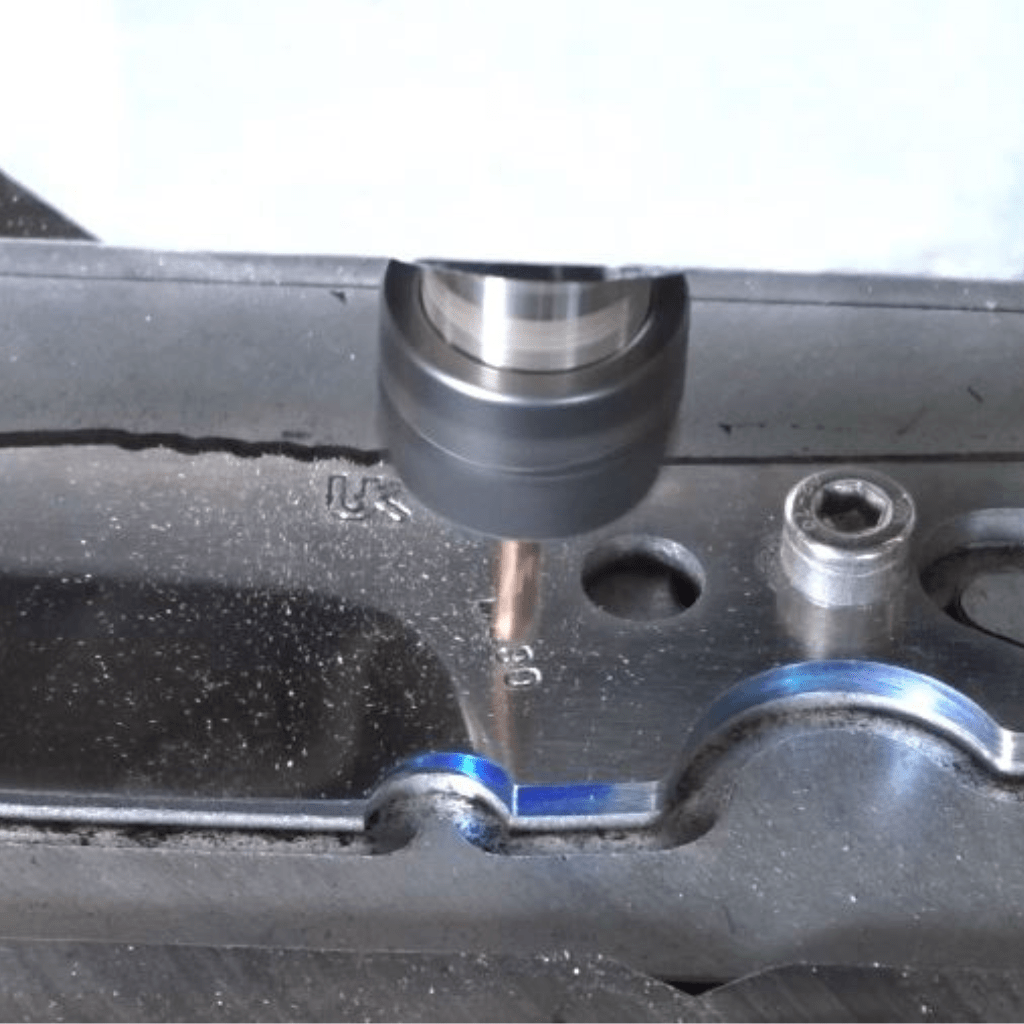

Engraving

The engraving is milled into the steel to a depth of about 0.2mm.

The company logo and steel number are on the left side of the knife and the customer's personal engraving is on the right side.

Steel hardening

The ground steel is hardened in a hardening furnace at a temperature of 800-1100 °C (depending on the steel).

For special steels, the blade is deep-frozen in liquid nitrogen between hardening and tempering to optimize the edge retention. The knife is then tested on a hardness tester.

Blade Finishing

I offer my blades either polished, satin stonewashed or with a Cerakote ceramic coating.

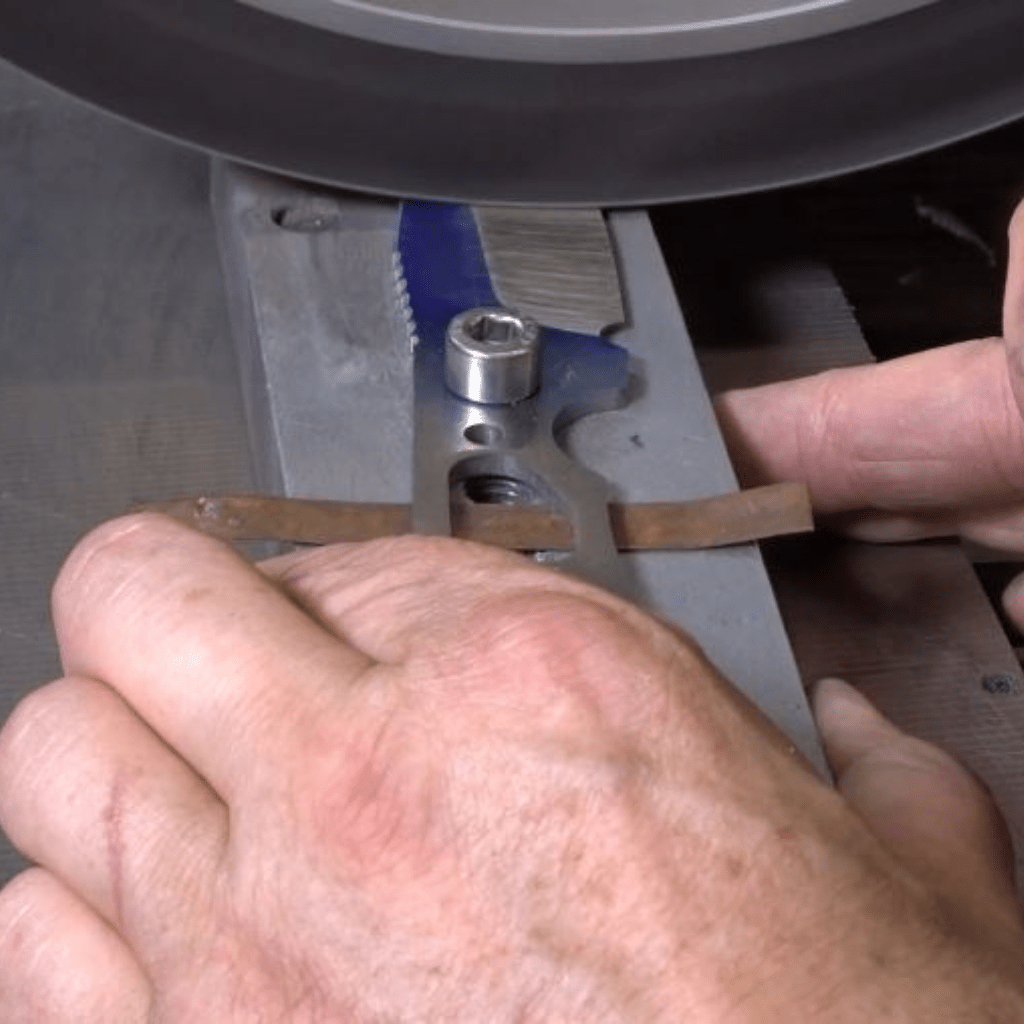

Grinding of the cutting edge

The final grinding is the last step on the knife blade and is done on the wet grinding machine.

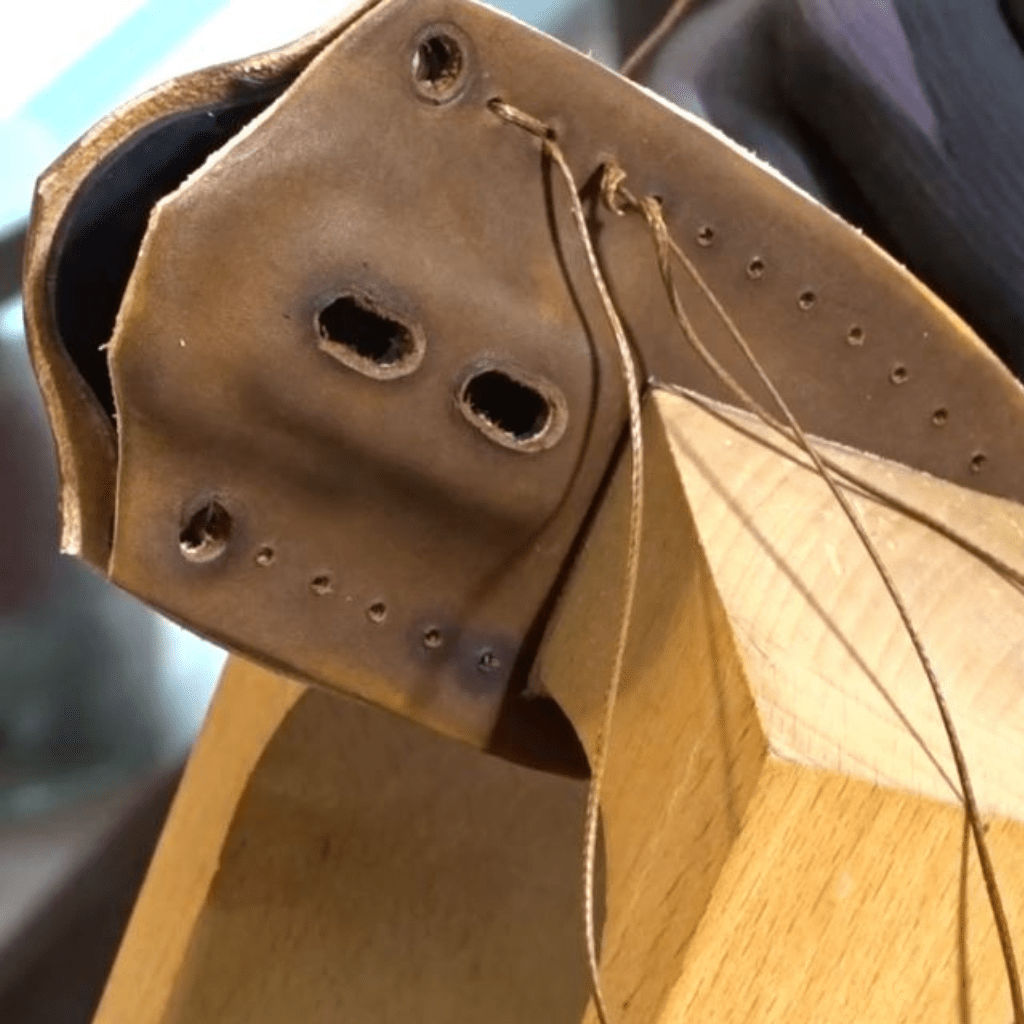

Production of the knife sheath

Our leather sheath is made with a lot of handwork from a plastic core and leather covering.

Here I link to a video that shows the production of the knife sheaths in detail.